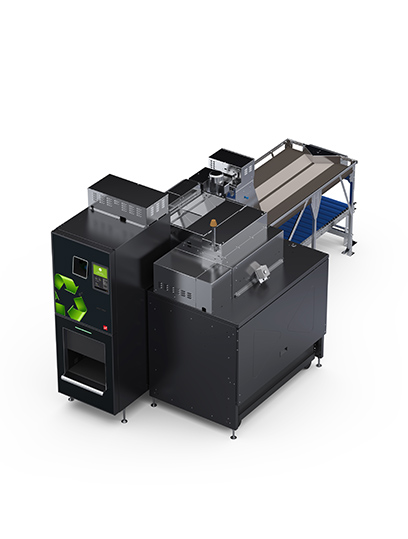

Our modular reverse vending systems

MonoSort technology

MonoSort technology

MonoSort technology is the ideal compacting solution for medium to high reverse vending requirements.

MonoSort combines a slim design that fits into almost every mounting area with a modular plug-and-play design. The system can manage up to five cabinets to ensure clean material separation and high performance at all times.

DualSort technology

DualSort technology

DualSort technology makes it possible for two empties acceptance units to share a background system. The collected empties can be easily sorted by type of material.

Consistently separate processing of the containers in the respective acceptance area ensures a 100 % redundancy. Uniform use of the individual components helps to increase the service life. The compactor capacity is doubled by using two compactors per enclosure.

Advantages at a glance

Features

- Space miracle with compact design

- Side-standing enclosures

- The roller conveyor runs underneath the bottle table

- Material separation possible inside the housing

- Removal direction possible front, rear or side

| Dimensions: | 1,715 x 600 x 1,080 mm (height x width x depth)* |

| Weight: | Approx. 330 kg |

| Electrical connection values: | 3L/N/PE, 400 V, 50 Hz |

| Power consumption: | Max. 650 W, 70 W Standby |

| Operating temperature: | +5 °C to +40 °C non-condensing |

| Wall opening: | 1,750 x 650 mm (height x width) |

*Deviations in the housing dimensions are possible due to add-on parts and accessories.

- Size: Euro pallet with 975 mm x 800 mm x 1,200 mm (height x width x depth)

- CE, DPG-certified

- UKCA (UK Conformity Assessed)

- Segregated collection according to material type is possible

Features

- Space-saving, high-performance sorting solution for medium to large volumes

- One compactor per housing ensures a fast and reliable flow rate with up to 60 containers/minute

- Material separation possible with up to 5 housings and/or inside housings

- Full-round system guarantees continuous operation, even when the container is emptied - for a non-stop coin return

- Plug-and-Play technology enables simple and cost-efficient installation and set-up

- Easy access and flexible removal direction, either right or left

- The unique FlexiSort conveyor belt makes it possible to transport almost any form and shape

- Flipper - the deflector with directly driven belt ensures the correct positioning of bottles, cans and beverage cartons

| Dimensions: | 1,715 x 600 x 1,080 mm (height x width x depth)* |

| Weight: | Approx. 330 kg |

| Electrical connection values: | 3L/N/PE, 400 V, 50 Hz |

| Power consumption: | Max. 650 W, 70 W Standby |

| Operating temperature: | +5 °C to +40 °C non-condensing |

| Wall opening: | 1,750 x 650 mm (height x width) |

*Deviations in the housing dimensions are possible due to add-on parts and accessories.

| Housings: |

|

| Capacity per enclosure: |

|

| Dimensions: | 1,750 x 910 x 1,350 mm (height x width x depth)* |

| Weight: |

|

| Electrical connection values: | 3L/N/PE, 400 V, 50 Hz |

| Power consumption: |

|

*Deviations in the housing dimensions are possible due to add-on parts and accessories.

- Size: Euro pallet with 975 mm x 800 mm x 1,200 mm (height x width x depth)

- CE, DPG-certified

- UKCA (UK Conformity Assessed)

- Segregated collection according to material type is possible

Features

- 2 compactors per housing

- Removal direction right or left

- Material separation with several housings

- Up to 7 enclosures possible

- Dynamic resorting; the equipment remains operational even if a collecting container is emptied.

| Dimensions: | 1,715 x 600 x 1,080 mm (height x width x depth)* |

| Weight: | Approx. 330 kg |

| Electrical connection values: | 3L/N/PE, 400 V, 50 Hz |

| Power consumption: | Max. 650 W, 70 W Standby |

| Operating temperature: | +5 °C to +40 °C non-condensing |

| Wall opening: | 1,750 x 650 mm (height x width) |

*Deviations in the housing dimensions are possible due to add-on parts and accessories.

- Size: Euro pallet with 975 mm x 800 mm x 1,200 mm (height x width x depth)

- CE, DPG-certified

- UKCA (UK Conformity Assessed)

- Segregated collection according to material type is possible

Features

- Enclosure positioned transversely

- 1 compactors per housing

- Removal direction right or left

- Material separation with several housings

- Up to 7 enclosures possible

- Dynamic resorting; the equipment remains operational even if a collecting container is emptied.

| Dimensions: | 1,715 x 600 x 1,080 mm (height x width x depth)* |

| Weight: | Approx. 330 kg |

| Electrical connection values: | 3L/N/PE, 400 V, 50 Hz |

| Power consumption: | Max. 650 W, 70 W Standby |

| Operating temperature: | +5 °C to +40 °C non-condensing |

| Wall opening: | 1,750 x 650 mm (height x width) |

*Deviations in the housing dimensions are possible due to add-on parts and accessories.

- Size: Euro pallet with 975 mm x 800 mm x 1,200 mm (height x width x depth)

- CE, DPG-certified

- UKCA (UK Conformity Assessed)

- Segregated collection according to material type is possible

Equipment

Omega 360° recognition

Omega 360° recognition

Omega 360° ensures reliable recognition of containers – even if they are not cylindrical or deformed. This makes you well prepared for future forms of packaging.

Cleaning brushes

Cleaning brushes

Dirt and foreign parts are removed in a targeted manner by the cleaning brushes, thus minimizing the personnel costs for cleaning. The brushes clean the belt automatically during operation.

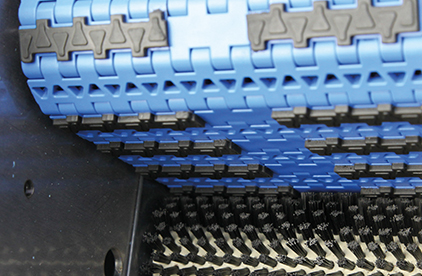

FlexiSort and switch

FlexiSort and switch

FlexiSort technology ensures the safe transport of all empties. Proper compacting is achieved by activating the diversion of containers into the compactors by means of separately driven switch. Due to the high speed of the switch, the containers get into the SafeCrush as quickly as possible.

SafeCrush

SafeCrush

Draws in PET bottles, cans as well as thick-walled containers and ensures reliable disposal.